- Home

- Mold Making

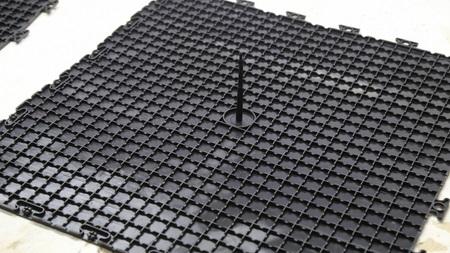

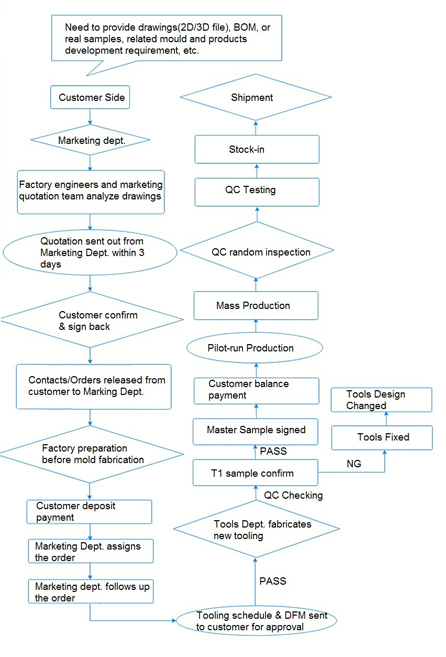

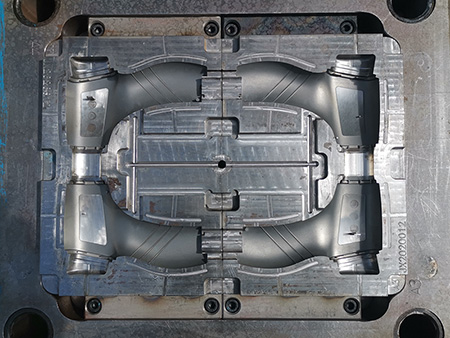

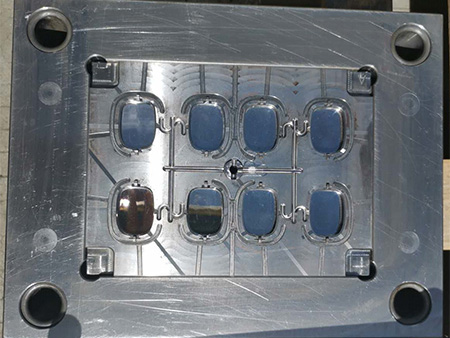

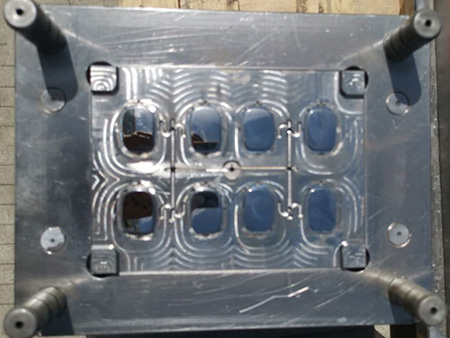

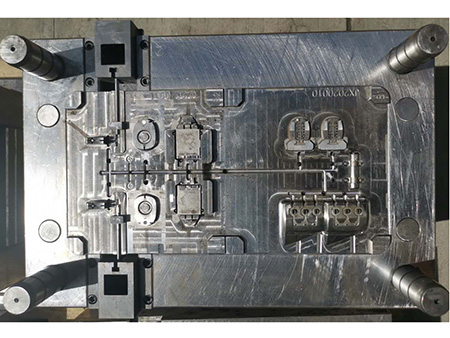

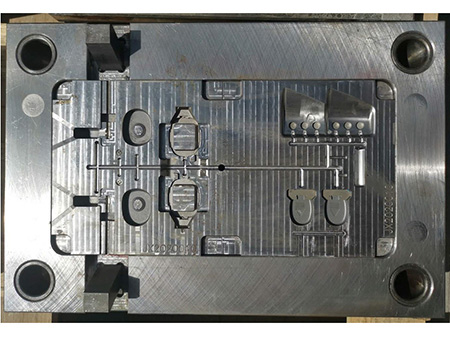

Honest Mould offers services for injection mold and silicone mold design and production, with services ranging from mold design to mold production, and mold adjustment.

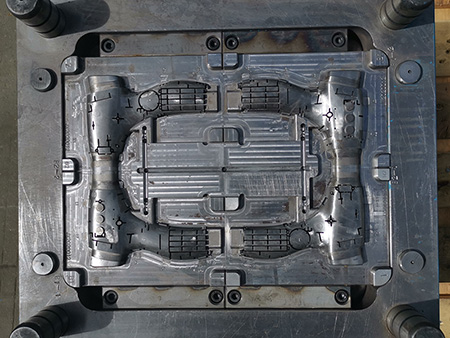

We have developed thousands of mold sets over the past 20 years, and now have the capacity to manufacture molds as large as 2m*1.3m and a weight of 14.8 tons.

- Quotes in 48 hours

- Multi-cavity mold design

- Our team provides free guidance during the molding process.

- Insert molding

- Overmolding

- Low volume production parts

- Tight tolerance

- Custom colors

- Complex and large parts

- Sample parts

- ISO 9001 & BSCI

- Presses ranging from 80 to 1100 ton

Rapid Prototyping

Rapid prototyping service at Honest Mould offers exceptional convenience for low volume production or pattern production for testing before mass production. We manufacture a wide range of large, complex parts, available in both plastics and silicone.

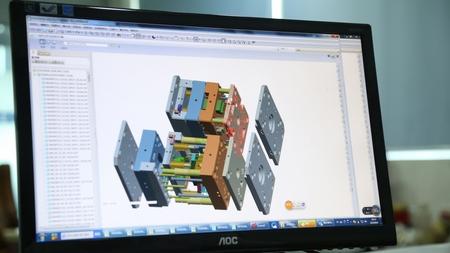

Experienced Tooling Design & Computer Program

With over 20 years of manufacturing experience, Honest Mould mold design team is good at designing molds, as long as customers provide us with samples or 3D drawings. The service has been confirmed to customer requirements and helps to save a lot of time and money for our customers in early production stages, as well as decreases overall production time.

Good Materials

Honest Mould will select suitable raw materials according to your desired product types and mold service life. Material types including a wide array of steel types from the Japanese company DAIDO Steel, and Swedish companies ASSAB, LKM, and ArcelorMittal.

These steel materials feature the following benefits:

- Outstanding corrosion resistance

Most resins and additives are corrosive and will eventually corrode the mold cavity surface and cause deformations, thus influencing the product quality. Honest Mould chooses high corrosion-resisting steel to manufacture injection molds to guarantee the finished product quality. - Excellent abrasion resistance

Raw materials with added glass fiber, inorganic filler or pigment results in significant levels of abrasion on the mold cavity surface while flowing in the cavity at high speeds. A highly abrasion resistant steel used to produce molds ensures the abrasion resistance of the product surface and thus, ensures injection molded part accuracy. - Excellent thermal stability

An excellent dimensional stability is critical to the product. During the molding process, the temperature in mold cavity reaches over 300℃ which is why steel with a high thermal stability is needed, as it prevents finished product deformation caused by mold deformation.

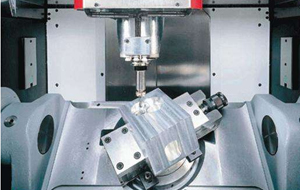

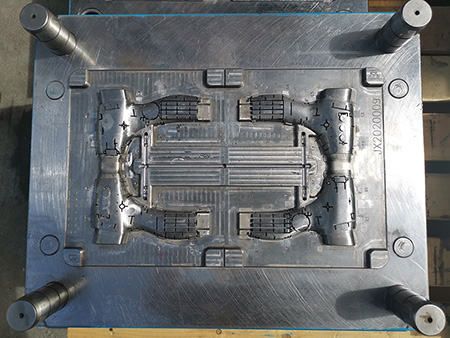

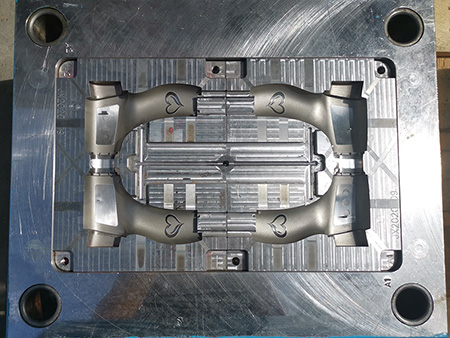

Precision Machining

Honest Mould has 4 CNC machining centers with a travel of 600-1580mm, 15 CNC drills, 8 EDM machines with a travel of 300-980mm and 3 wire EDM machines, ensuring we can meet all customer mold precision requirements.

Molds at Honest Mould are highly recognized by customers from all over the world, including electronic molds, appliance molds, medical device molds, mold for fitness equipment production, and more.

With more than 20 years of experience, we offer expert plastic mold design, mass production services, a variety of finishing options, and carry out extensive testing to ensure that all respectful customers can be satisfied with our highest possible quality of plastic mould and parts.