- Home

- Injection Molding and Compression Molding Service

- Plastic Injection Molding

Since 1993, Honest Mould has been a custom plastic mold manufacturer, delivering top of the injection molds. We utilize the integration of mold and injection machines to offer our customers reliable plastic injection molding service, encompassing everything from mold design to part production.

Our facilities are outfitted with 20 single-shot injection molding presses ranging from 80-1100 tons and 11 double-shot injection molding machines ranging from 140-350 tons.

Different material types available for plastic injection molding:- Polycarbonate (PC)

- ABS

- Polyphenylene (PPE)

- PPR

- Other

-

-

- Camera tripod

We began to provide this camera tripod for a prominent brand in 2010, now at a grand total of 5 million tripods. This product is 250mm long and weighs 243g, with each leg containing 10 balls that are 35mm in diameter. The balls are double-shot injection molded with ABS and TPE materials. The tripod is also bendable and flexible to attach the camera in different environments.

-

-

-

-

Google product display unit

We offered plastic injection molding for Google. This electronic display was specially designed for a prominent brand, and consists of the main display housing (251*70*200mm, 1073g) and two display seats (153*200*26mm, 303g). The mold design and manufacturing set were both completed by us, and the display unit was then finished through a process involving injection molding, insert molding, spraying, screen printing and assembly. A final UV spray coating ensures the product is more aesthetically appealing and durable in different environments. The white color was added according to customer requirements.

-

-

-

-

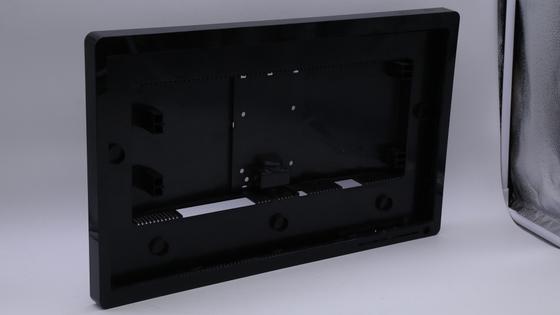

Minicomputer housing

In 2010, Honest Mould independently developed this minicomputer housing. By analyzing popular minicomputers on the market at the time, we designed the minicomputer’s housing and applied for a product appearance patented before we developed the mold and began mass production. This replaces traditional desktop case housing in domestic markets and met with significant popularity. Product size: 238*270*50 mm.

-

-

-

-

Remote control

During a period between 2002 to 2008, we were contracted by a prominent company to produce 5000 remote controls/month. The customer was pleased with our product quality and production management, leading to us undertaking nearly all of their remote control orders. We were also responsible at the time for the design and manufacturing of plastic injection molds.

-

-

-

-

Drones holder

This drone holder was ordered by an American company, and Honest Mould is responsible for the mold design and manufacturing according to the product designs. The product was then formed through an injection molding and over molding process, before being delivered to the customer, who assembled the circuit board. The assembled product is 415*204*85mm and weighs 1748g.

-

-

-

-

Fitness equipment housing

In 2003, an America fitness equipment manufacturer turned to Honest Mould for the production of treadmill housing molds, with the contract for injection molding and plastic housing of the entire treadmill awarded to us. We still carry out orders for this customer every year. (Red fitness equipment housing is 680*352*90mm, 935g)

-

-

-

-

Molded clear plastic container

In 2017, a customer came to us with an order for mold production and injection molding of a clear plastic container. This two-layer product weighs 1897g, including a cylindrical shell with a size of 370*280*280mm and an inlayer injection molded using a clear PC material with a complex structure.

-

With more than 20 years of experience, we offer expert mold design, mass production services, a variety of finishing options, and carry out extensive testing to ensure that all respectful customers can be satisfied with our highest possible quality of mould and parts.