- Home

- Quality Assurance

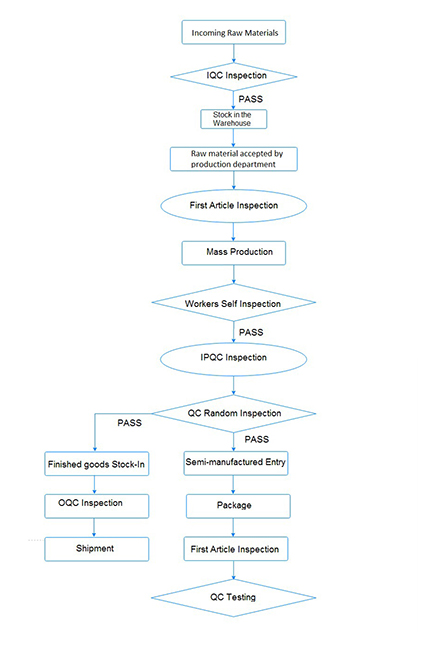

Quality is vital to an enterprise, so we persist in "focus on customers" as quality management concept and conscientiously implement the ISO 9001:2015 standard. With strict internal quality control system, our quality engineering has integrated into each aspect of mold manufacture, realizing all-round inspection on machined components and die sets to ensure high precision and quality. In the injection molding area and assembly workshop, we have established quality assessment procedure for each step from purchase, production, assembly, packing and shipping, to make sure the customers get the best quality products and service.

Quality Commitment

*The qualified rate of finished products ≥ 99.5%

*The first pass rate of manufacturing process ≥ 97%

*Customers complaint per half a year ≤ 4 times

Strict testing

Our testing department is equipped with a tensile test environmental chamber, salt spray chamber and other testing equipment to control and guarantee product quality, ensuring only 100% qualified products are delivered to the customer.

Plastic injection molding parts and silicone hot press compression molding parts are widely used in electronics,

home appliances, communication equipment and toys. At Honest Mould, our entire product catalogue conforms to LFGB and FDA requirements,

while our silicon house-ware products meet EU food grade standards.

Our products are popular with customers all over the world, with long-term cooperative relationships established with customers in America,

Japan, Vietnam, EU and other countries.

From all of us here at Honest Mould, we’d like to thank you for your trust!

Laboratory

We set up our laboratory according to Customer’s standard.

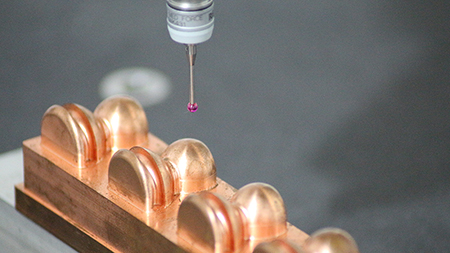

Coordinate Measurement Machine(CMM):

Three dimensional measuring instrument is mainly used for three dimensional measurement. It can measure the size, shape and position tolerance and free surface of mechanical parts with complicated shapes, with the measurement accuracy up to 0.0001mm. It is widely used in the precision detection of mold manufacturing, plastics parts, hardware and metal parts.

High and low temperature tester:

The sample was put into a constant temperature and humidity test chamber, with the temperature at 65℃ and the relative humidity at 95%. After 48 hours of testing, it proved that there was no oxidation, rusting and treatment layer falling off on the sample surface.

2D projector:

It is mainly used in the precision measurement of two-dimensional dimension, with the measurement accuracy up to 0.001mm. It is widely used in the precision detection of mold manufacturing, electronics, hardware and metal parts.

Salt spray test:

With 5% NaCL solution, the PH value was between 6.5 and 7.2, the spray pressure was 1± 0.2kg /CM, the temperature in the saturated barrel was 47±1℃, and the temperature in the laboratory was 35±1.1℃. After spraying for 12hrs, there was no corrosion point, oxidation, surface treatment layer separation or peeling on the sample surface.

Surface hardness test on metal products

For this HR-150A type Rockwell hardness tester is specially for the hardness testing on the metal and hardware parts, the source of hardness reading is the data shown from the dial and easy to use.

Surface hardness test on plastic products

Cut the special test 3H pencil flat, close to the coating surface at a 90-degree angle, apply a force of 500g, carve 4-5cm on the coating surface at a speed of 1cm/S, and then wipe off the pencil marks with a cotton cloth, no scratches leave on the surface.

Note: each test must be performed on both sides and the center of test objects.

With more than 20 years of experience, we offer expert mold design, mass production services, a variety of finishing options, and carry out extensive testing to ensure that all respectful customers can be satisfied with our highest possible quality of mould and parts.